Everything you need to know about formulating an automotive detergent

Brazil vibrates with a passion for cars, and a fundamental aspect of this connection is the relentless pursuit of an impeccable vehicle. Car cleaning has transcended obligation, becoming a true hobby for many who dedicate their weekends to making their ‘toys’ shine and smell good. This enthusiasm has driven the emergence of a specialised and increasingly technical market, full of products that promise hygiene and beauty for cars.

Amidst a vast array of options – dashboard silicones, tire polishes, wheel arch trimmers, APCs, air conditioning sanitizers, waxes, polishes, degreasers, crystallizers, windshield wipers, washer fluids, anti-fog glass cleaners, and air fresheners – there is one protagonist: the famous automotive "shampoo".

In this article, we will explore the technical nuances behind a balanced and functional formulation that meets manufacturers' primary desire: excellent cost-effectiveness.

To better understand the concepts that will be covered, we recommend reading our article on dishwasher detergents, we establish essential foundations to develop any detergent formulation that requires foam and viscosity.

Based on the principles already elucidated, we can state that Automotive Detergent (a more technically appropriate term for this product class) is nothing more than an adaptation of the dishwashing detergent concept. Its base composition is similar, but enriched with specific ingredients to meet the specific demands of vehicle cleaning.

However, what are the crucial technical characteristics of a good automotive detergent?

Ensuring intense shine

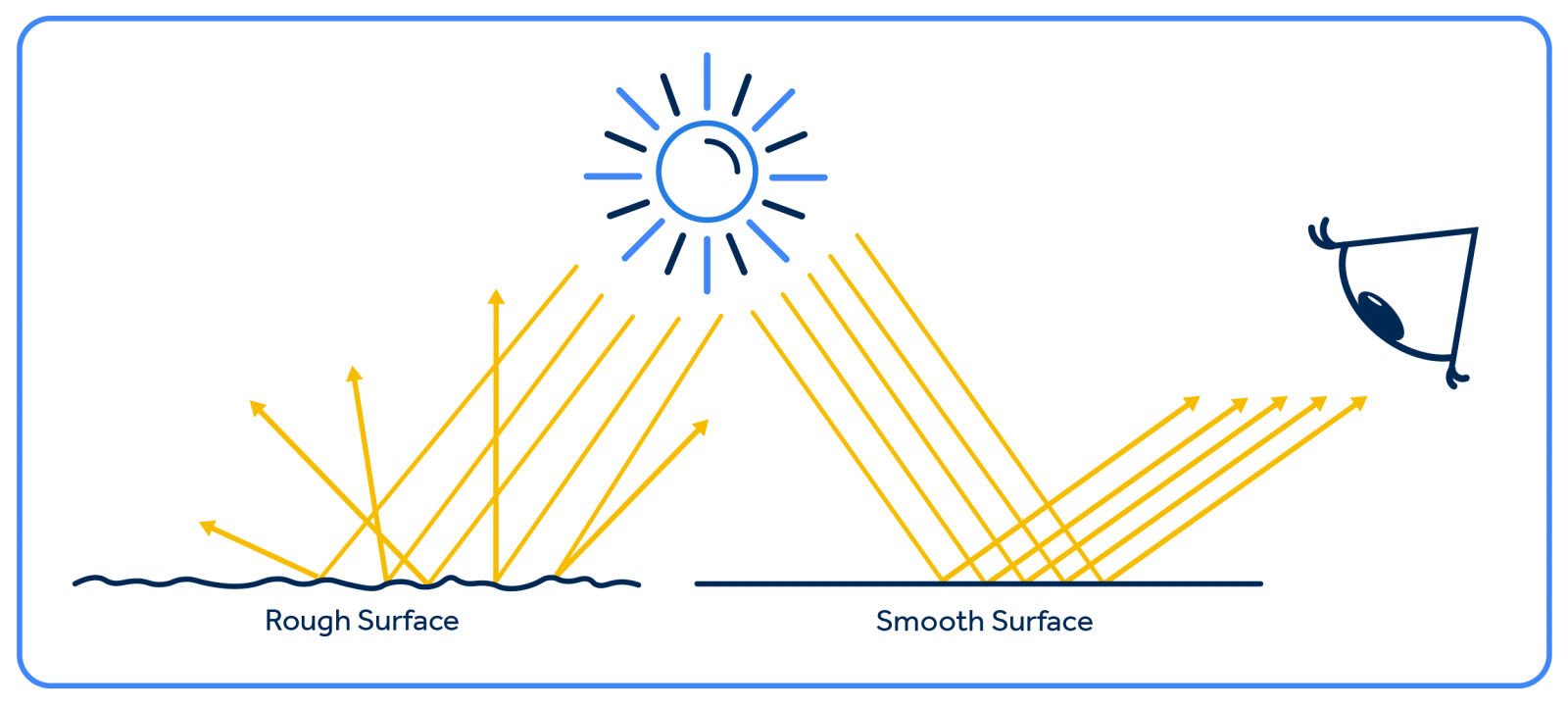

Gloss is the result of light reflecting off a surface. The smoother and more uniform the surface, the more light rays will be reflected in the same direction and angle, intensifying the perceived gloss. In contrast, uneven surfaces scatter light rays, decreasing gloss.

The application of waxes, for example, promotes shine by filling in micro-irregularities in the paint, making the surface more homogeneous and favoring uniform light reflection.

Therefore, the belief that adding wax directly to the car shampoo formulation will enhance shine does not always hold true. This is mainly due to the high concentration of anionic surfactants (such as sulfonic acid and sodium lauryl ether sulphate) present in the formulation, which have high solubility. This characteristic causes the wax to become emulsified and have a low ability to adhere to the vehicle's surface. Even if a small portion of wax manages to adhere, polishing would still be necessary to even out the surface and, consequently, generate the desired shine.

In some cases, self-leveling silicones could be considered as a way to get shine without polishing. However, they tend to be anti-foaming and difficult to stabilize in aqueous formulations, compromising overall solubility of the product.

So, how can we achieve a product that provides shine?

The best technical approach for an automotive detergent that truly delivers shine lies in its deep cleaning, easy-to-rinse, and anti-redeposition properties. Residue the product itself, which isn't rinsed properly, or dirt that hasn't been removed, can leave the surface uneven, detracting the final shine.

Therefore, the ideal approach is to formulate an easily rinsable product (reducing the concentration of amines such as betaines and amides) and incorporate an effective dispersant, such as Sodium Polyacrylate. The dispersant plays a crucial role in ensuring that the dirt removed (soot, dust, clay) during the foaming process does not redeposit on the cleaned bodywork. By keeping the surface free of solid particles, its smoothness is preserved, and the vehicle's natural shine is enhanced.

Additionally, a good dispersant acts as an anti-spotting agent, preventing those hard-to-remove white stains that can appear if water drops dry on the surface. This is because water contains minerals and other substances that, when dry, adhere to the paint. The presence of a dispersant significantly minimizes this problem.

Want to ensure an even more intense shine?

For superior shine, we suggest offering the customer a specific polishing product to apply after washing. An aqueous silicone oil emulsion with a low concentration of surfactants is an excellent option in this case. Click here to find out more.

Foam: value perception and cleaning tool

Foam is undoubtedly one of the most desired characteristics in an automotive detergent, for two main reasons:

- Perception of Value: For consumers, abundant foam is often associated with high cleaning efficiency. While this correlation isn't always true (excessively foaming ingredients may be unsuitable for the application), foam creates a strong perception of value.

- Contact Time: Technically, foam plays a key role in increasing the product's contact time with the vehicle's surface. A dense, stable foam flows more slowly, allowing cleaning agents to work longer on the dirt, optimizing removal.

To achieve a rich, dense lather, the key lies in the strategic combination of surfactants in the formulation. As already discussed in the article on dishwashing detergents, the ideal ratio of 70% to 30% between Sulfonic Acid and Sodium Lauryl Ether Sulfate for the formulation base remains relevant.

To improve foam stability and density, the addition of Coco Starch Propyl Betaine or Coconut Fatty Acid Diethanolamide is valuable. However, it's crucial to limit the concentration of these ingredients, as excess can cause them to adhere to the surface, making rinsing difficult and compromising the final shine.

Foam quality during application also depends on the protection of anionic surfactants (sulfonic and lauryl) against calcium (Ca), magnesium (Mg), and iron (Fe) ions commonly found in water. For this, the use of sequestrants is essential. EDTA is a widely used sequestrant, but more sustainable alternatives, such as Nouryon's Dissolvine GL47-S (distributed by Macler in Brazil), are available on the market. Click here and learn about this solution.

Cleaning performance: degreasing and anti-redeposition action

Nonionic surfactants, preferably with an HLB (Hydrophilic-Lipophilic Balance) between 11 and 13, are crucial components for the cleaning performance of an automotive detergent. These surfactants generally have excellent degreasing capabilities.

Additionally, its ethoxylated portion contributes to the formulation's dispersing capacity, aiding in the removal of solid particles such as dust, clay, and soot. Therefore, for a high-performance product, the inclusion of a nonionic surfactant with these characteristics is essential. It will initially remove oily dirt, but it will also penetrate and remove traffic film.

Traffic film is a complex type of dirt resulting a combination of dust, asphalt, combustion residue, rain, and other environmental impurities. It is one of the main obstacles to paint shine and is one of the most difficult sorts of dirt to remove. The synergistic action of nonionic surfactants and a good dispersant is essential to effectively combat this traffic film. An example of a high-performance nonionic surfactant, surpassing Nonyl Phenol 9.5EO and Lauryl Alcohol 7EO in efficiency and cost, is Berol 175, manufactured by Nouryon and distributed by Macler in Brazil. Click here to learn more.

Isogen PRO-D: technology and solution

The information presented so far reflects the most widely used formulation technologies and practices on the market. However, the landscape is constantly evolving, with the emergence of new technologies, molecules, and surfactant blends that offer excellent value for money, optimizing both technical performance and financial results.

In this context, Isogen PRO-D, manufactured by Macler, stands out. It is a synergistic surfactant base that eliminates the need for individual use of Sulfonic Acid, Sodium Lauryl Ether Sulfate, and Coco-Starch Propyl Betaine or Coconut Fatty Acid Diethanolamide.

Isogen PRO-D demonstrates superior efficiency compared to these traditional actives and significantly simplifies the manufacturing process, making it more agile and reproducible.

Core Formulation

By understanding the science behind car shampoo, manufacturers can create products that not only clean but also reveal the shine and beauty that car enthusiasts so value.

Just as we did for dishwashing detergent, we present here a practical guide for formulators, with dosage indications and product options for developing high-performance automotive detergent formulations.

Click on the banner below and download the core formulation.

Learn More

Perhaps one of the best-known chemicals used by Brazilian consumers, which has a dramatic influence on culture and behavior with regard to cleaning, is sodium hypochlorite, commonly known as “bleach.”

When the temperature changes, turbidity, phase separation, crystal formation, or changes in viscosity may occur. Two parameters are critical in this analysis: the fog point and the cloud point.

This article will discuss best practices for peroxide-based formulations and tips for developing a high-performance, cost-competitive, and highly stable product.

Our chemistry

We use our labs to create

intelligent chemical solutions balanced with your reality.

Products

We use our R&D center, our own laboratory with experienced professionals, to deliver intelligent chemical solutions in balance with your reality.